The shocking reason why your supply chain is weak- Business Process Management

What would you say is the unsung hero of your business? Let us put it to you that it is the supply chain management process.

In today’s demanding business environment that prioritizes flexibility, speed, quality, efficiency, effectiveness and innovation, a competitive supply chain strategy and its business process management is critical.

Even the legendary Elon Musk once famously echoed “The supply chain stuff is really tricky” (2017). So how then, do we begin to tackle this problem?

In this article, we’ll dive deeper into what business process management (BPM) is and how BPM ensures competitive advantage with your supply chain to achieve business success.

Let’s get started.

What is BPM and how does it relate to Supply Chain?

Why do burgers and fries go so well together? Or nachos and cheese? The same reason why your business process and supply chain correlates to each other’s success.

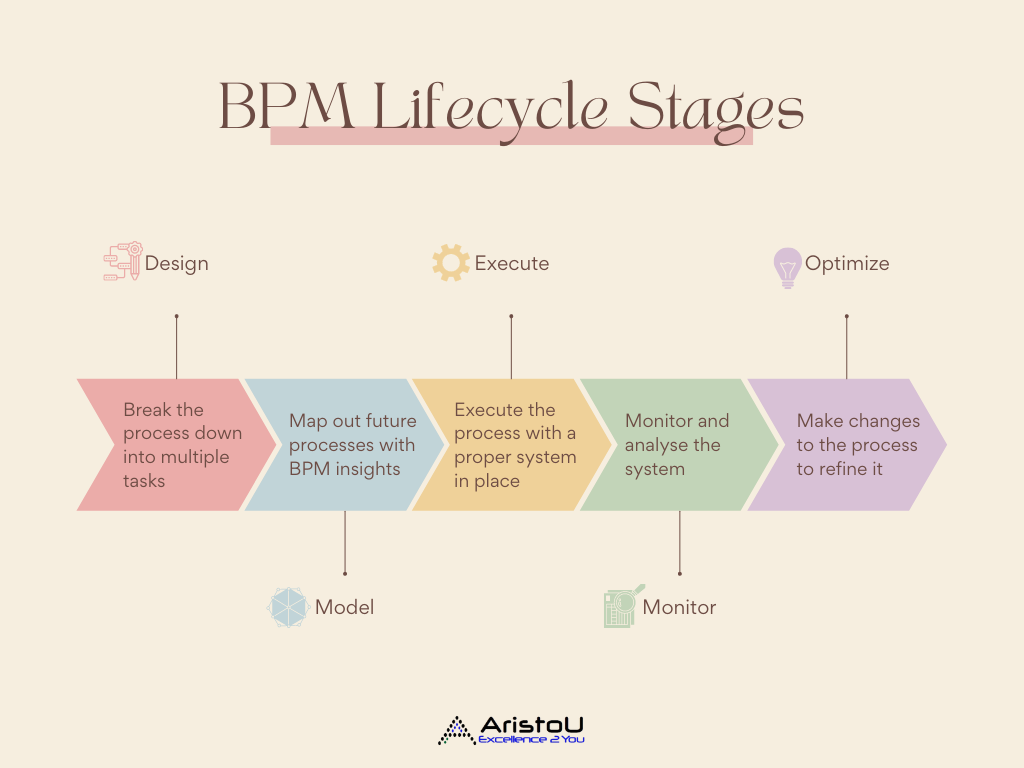

Let’s have a look at a simple diagram of the BPM lifecycle below.

Business process management (BPM) is an organizational discipline where a company analyzes all of its processes in totality and individually.

In today’s business environment that prioritizes flexibility, speed, quality, efficiency, effectiveness and innovation, a competitive supply chain strategy and its operational execution is critical.

BPM identifies areas of improvement to achieve the above in its supply chain strategy, as well as its execution of that strategy.

BPM can help enterprises view their supply chains comprehensively and optimize them for better performance. A few studies have shown a positive association between supply chain performance and organizational performance.

We can safely say that supply chain performance is critical for improving firm performance.

Below are 3 key sections on how establishing a strong BPM provides a stronger supply chain process:

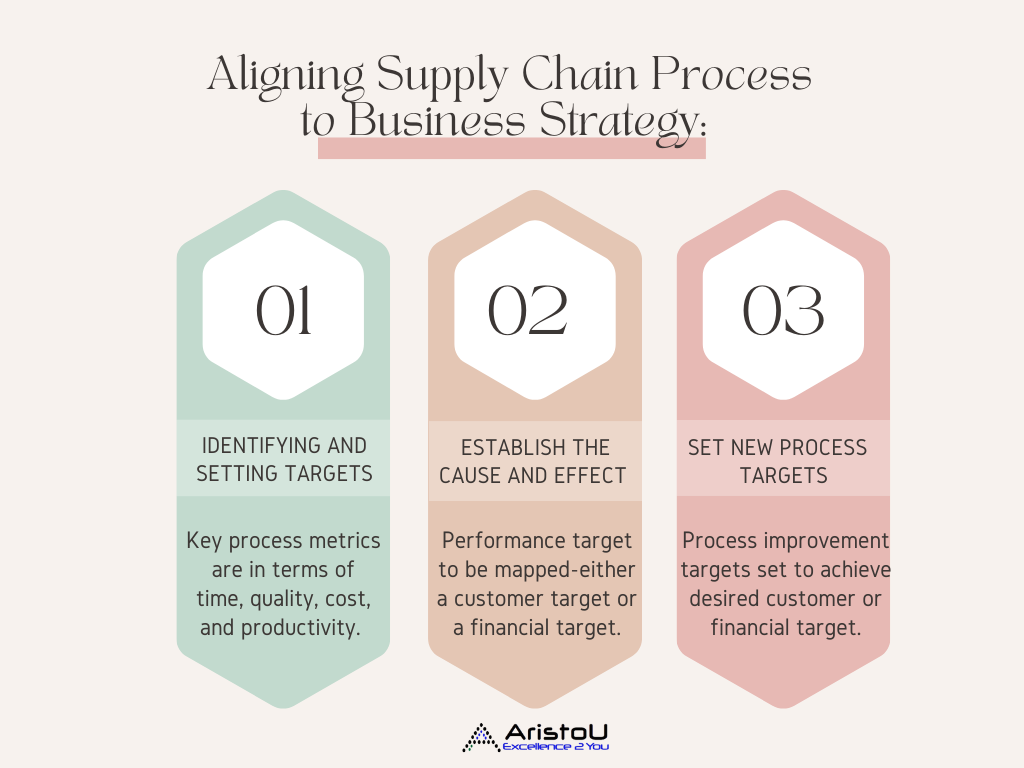

1. Aligning Supply Chain Process to Business Strategy:

-

Identifying and setting targets:

-

Supply chain and logistics processes are identified and targets are set for each process. The key process metrics are in terms of time, quality, cost, and productivity. The targets are established during workshops with suppliers, partners and customers.

-

-

Establish the Cause and effect relationships:

-

Establishing the relationship for each process allows the result of that process performance target to be mapped to the achievement of a particular business strategy – either a customer target or a financial target.

-

-

Set new process improvement targets:

-

Process improvement initiatives are defined and implemented and subsequent assessment is done to identify the process improvement achieved. New process improvement targets are then set to achieve the desired customer or financial target.

-

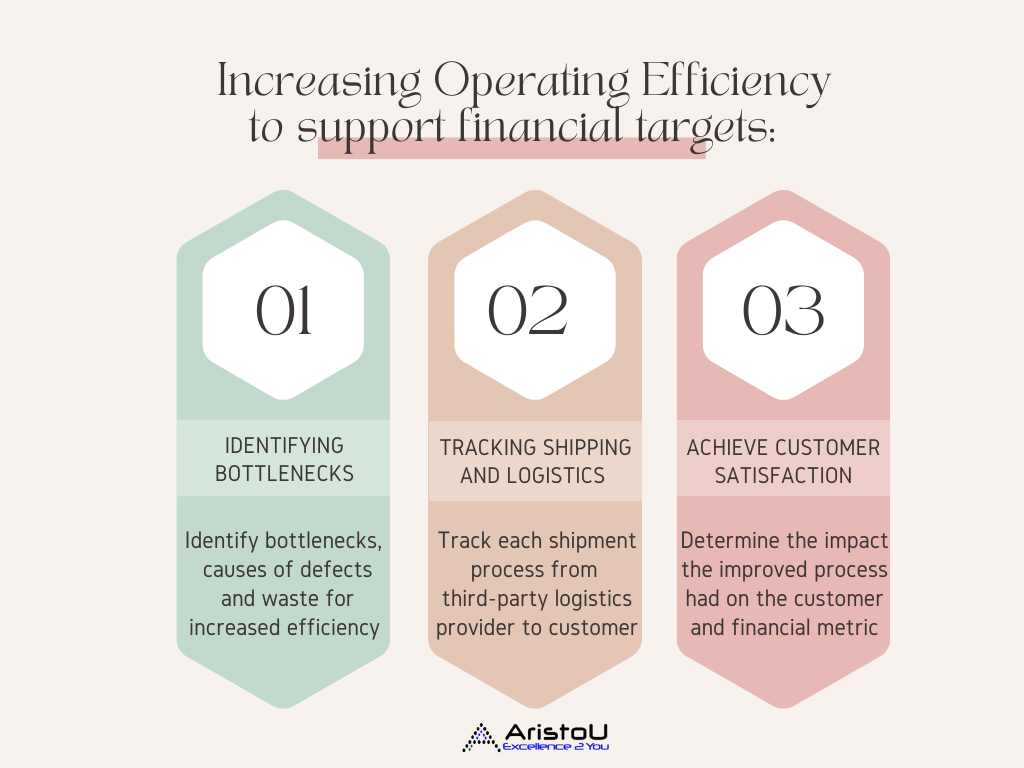

2. Increasing Operating Efficiency to support financial targets

-

Identifying bottlenecks:

-

A strong BPM consists of various tools and techniques to discover insight into current performance. It can identify bottlenecks, duplicate efforts, causes of defects and waste for increased efficiency.

-

For example, item returns are a huge problem for many manufacturers and retailers. Once retailers verify the cause of the bottleneck, they can begin to problem solve it.

-

-

Tracking shipping and logistics:

-

Using the issue on returns above as an example, retailers can track each shipment process from the time it was handed off to their third-party logistics provider. If a problem happened during the delivery of the shipment, the correct process would now be notified and managed via a call center agent to resolve the shipment issue with the customer instead of an automated re-delivery scheduled the next day.

-

By keeping the package in the field instead of returning to the dock, a company can save up to hundreds of dollars per item.

-

-

Achieving financial target and customer satisfaction:

-

Once we figure out the cause-and effect relationship for the returns process, we can then determine the impact that the improved process had on the customer and financial metric. A continuous improvement of the returns process lowers overall supply-chain costs.

-

This logistics process improvement results in a sustainable competitive advantage that yields increased customer orders.

-

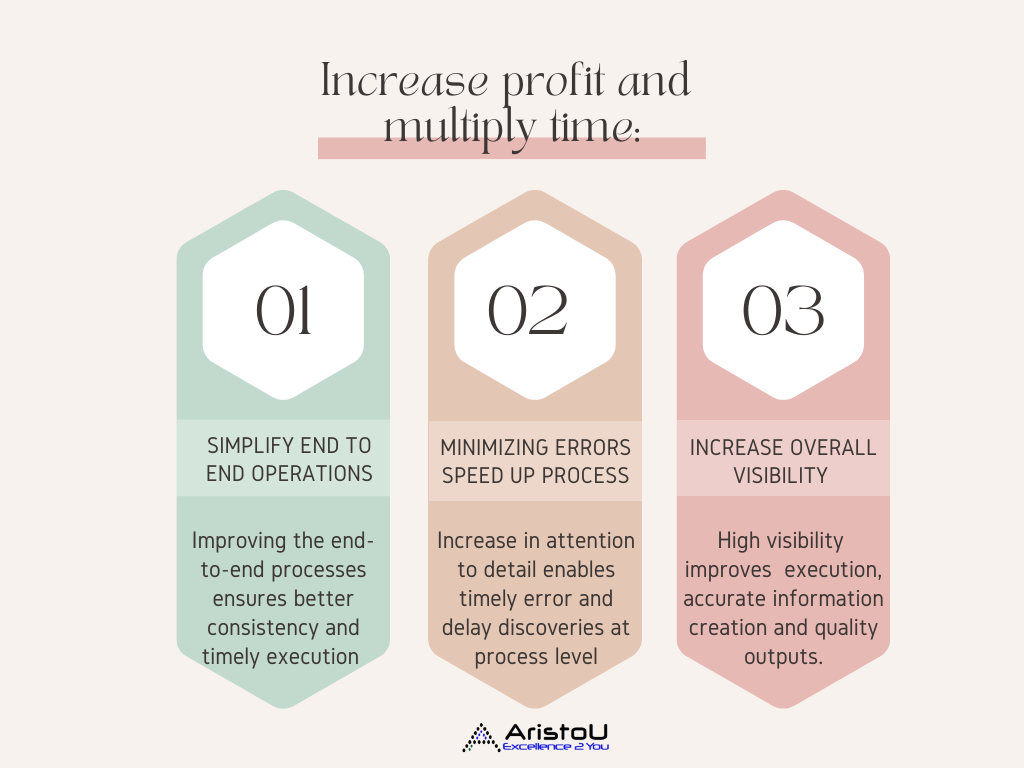

2. Increase profit and multiply time

-

Simplify end to end process across multiple departments:

-

One of the characteristics of a supply chain is that end-to-end processes cross multiple departments within and across organizations – a lot of handoffs have to occur. Improving the management of those handoffs ensures better consistency and timely execution. T

-

his speeds up processes and minimizes errors – reducing/optimizing inventory.

-

-

Minimizing Errors and Speeding up Processes:

-

When the process is sped up with minimal errors, it results in saving time and money. An increase in attention to detail within the supply chain enables companies to discover errors and time delays at a process level, utilizing BPM methods to improve them.

-

-

Increase Visibility Across Suppliers and Partners:

-

Imagine a world where any data you need, you get. BPM enables high visibility into activities to better manage timely execution, accurate information creation, and quality outputs. For example, a strong supply chain will understand which of the 30 quotes in the process and can find 4 trading partners who can best supply that item quality in the allocated time.

-

Managing by process also grows customers’ satisfaction and contentment—at the best price.

-

Applying the BPM discipline achieves process improvements that lead to organizational performance improvements – especially in the case of supply chain management.

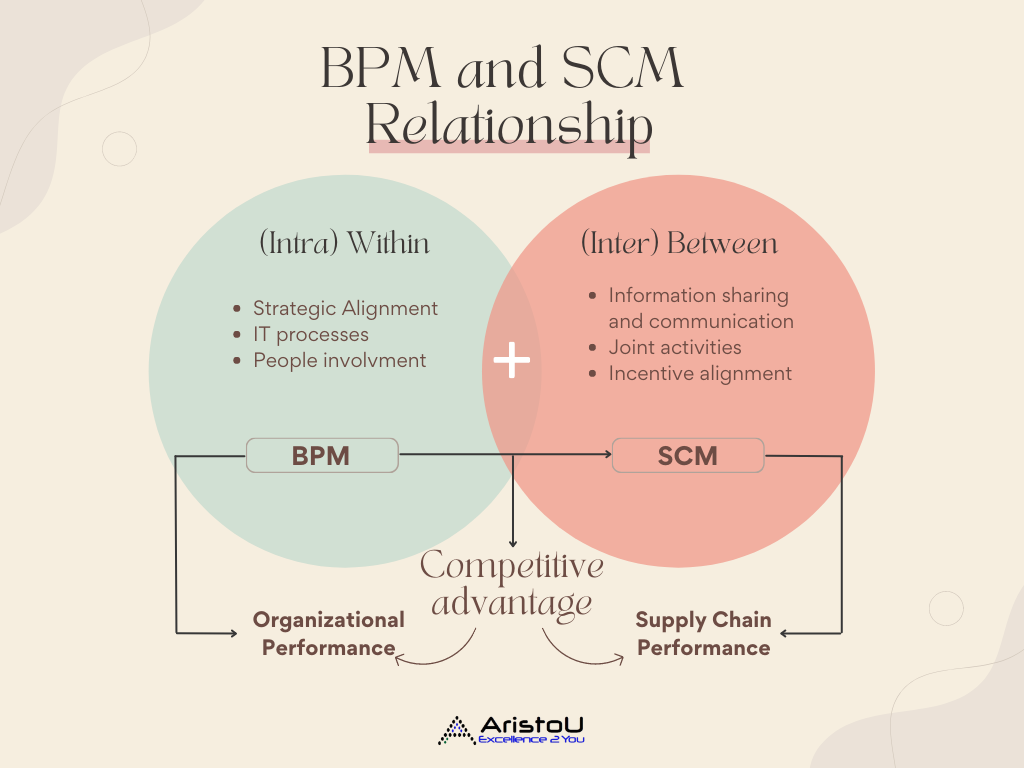

The relationship between BPM and SCM is at its peak when all the parts within (intra) and between (inter) are seamlessly integrated, creating a collaborative competitive advantage. This will result in both organizational performance and supply chain performance.

See below for the BPM and SCM relationship chart:

Leave a Reply