Sales and Operations Planning- Part 2

According to a report by Deloitte, companies that implement integrated sales and operation processes (S&OP) are 67% more likely to forecast revenue growth accurately compared to those without such processes. (Deloitte 2023)

In Part 1, we explored how Sales and Operation Planning acts as the linchpin between strategic sales and operational efficiency, fostering organizational harmony. Now, it’s time to transition from theory to action.

From overcoming challenges to embracing agile processes, we’ll delve into real-world success stories and provide actionable tips to fortify and optimize your business’s S&OP approach.

Let’s dive in!

One of Aristou’s customers exemplifies the power of Sales & Operations Planning (S&OP) in revolutionizing their operational landscape.

This section explores the challenges faced by them; such as disjointed sales forecasting and production scheduling, and how they overcome these hurdles with the support of Aristou’s expertise.

Implementing a robust S&OP framework that seamlessly integrated sales, operations, and finance functions, our client fostered cross-functional collaboration and embraced data-driven decision-making.

Through meticulous planning and execution, our client achieved great outcomes, including significant reductions in lead times, optimization of inventory levels, and heightened customer satisfaction.

We continue our dialogue with Aristou’s operational expert, Director KL Ang, as we delve deeper into our customer’s S&OP journey.

According to Mr Ang, there are several indispensable prerequisites for companies earnest about integrating Sales and Operation Planning (S&OP) processes effectively.

1. Training

-

-

Key managers and executives slated to partake in S&OP must undergo comprehensive training. Understanding their functional roles within the process is imperative. Collaboration across functions, including finance and sales, is crucial for achieving overarching business objectives.

-

2. Participation:

-

-

Active engagement and unwavering commitment from all involved are non-negotiable. Clear articulation of process components, individual expectations, and the significance of each function’s contribution is essential. Emphasizing the consequences of underperformance underscores the seriousness of the endeavor.

-

3. Expectations:

-

-

Establishing behavioral guidelines for both intra- and inter-meeting interactions is paramount. Maintaining a unified dataset ensures consistency and reliability. Structuring S&OP meetings with clear leadership, agendas, and empowered representation fosters productive discourse. Addressing cross-functional issues and closing performance gaps are central objectives.

-

4. Software Infrastructure:

-

-

The absence of an effective Material Requirements Planning (MRP) module software poses a significant challenge. By adopting an integrated system capable of generating plans based on demand forecasts and sales orders, utilizing simple Bill of Materials (BOMs), companies can streamline operations and enhance efficiency.

-

Mr. Ang emphasizes the importance of implementing appropriate metrics to effectively monitor progress, achievements, and challenges within the S&OP process.

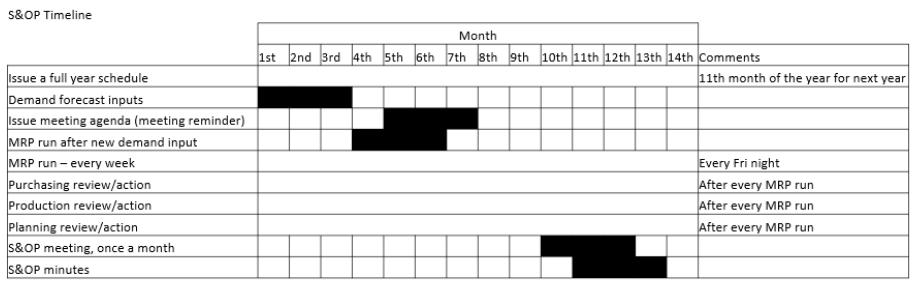

Furthermore, he suggests organizing S&OP meetings regularly and proactively planning a full-year schedule in advance. This preemptive approach minimizes scheduling conflicts and eliminates excuses for non-attendance, ensuring the continuity and effectiveness of the S&OP framework.

“All the various plans and recommended activities are tied to each other to help the business sell as the market demands them. All production orders and purchase orders, required as far out as the demand forecasting period, 6 months,1 year, 2 years depending on the business needs are triggered from a single click.”

“Hundreds of orders can be created immediately or changed by the MRP tool immediately, giving infinite improvements in productivity without manual errors vs creating or changing orders manually one at a time.”

Any change in demand or new sales orders would trigger an integrated change to production and purchase orders so the team can focus more on problem solving in the production floor or expedite the late delivery of purchases or negotiate lower vendor prices with more compact, focused resources.

With the implementation of the S&OP process and integration of an MRP tool, our team and management gain invaluable clarity. Now, we can swiftly identify delinquent sales orders, pinpoint production or raw material shortages, and enhance forecast accuracy without getting bogged down in lengthy debates or firefighting sessions.

By addressing these challenges promptly, our cross-functional team can focus on proactive problem-solving and value creation. With greater confidence in our strategies, we can navigate towards success with clarity and efficiency.

Top tips to strengthen S&OP

Top of the list: Expertise and experience is worth every penny.

Mr Ang explains: “Engage the expertise of seasoned consultants who possess a track record of successful implementations. Their guidance minimizes trial and error, boosting team morale and ensuring a smoother transition.”

“Appoint a capable leader to establish guidelines, foster teamwork, and define expectations for both the collective and individual contributors. Regular meetings are essential, with active participation emphasized. Focus discussions on exceptions and assign sub-team leaders to tackle issues outside of the meetings. Utilize metrics to gauge performance and identify emerging challenges.”

In addition, there is wisdom to recognize that adapting to these changes can be daunting, especially for the designated S&OP leader.

Success may not come instantly, but rather through iterative refinement. S&OP is an ongoing journey, responsive to evolving business dynamics. Flexibility and a willingness to embrace change are paramount.

Mr. Ang underscores the importance of teamwork, stressing the cohesive and harmonious functioning of all team members to navigate the complexities of the S&OP process effectively.

Importance of mastering your S&OP processes

Mr Ang continues to highlight the coordination of multiple functions is necessary for any manufacturing or distribution companies striving for growth.

“Each function necessitates distinct skills, often with different objectives that may intersect with overall business goals. S&OP serves as the linchpin, aligning and harmonizing all functional teams towards overarching business objectives, thereby preventing conflicting agendas.”

When functional teams operate in isolation or fail to contextualize their efforts within broader business objectives, chaos ensues, hindering the attainment of optimal results.

“Besides, disjointed teams serve no purpose in effective management practices, as they impede productivity and jeopardize organizational coherence.”

In conclusion, investing in sales and operation planning, guided by experienced professionals, yields significant returns, states Mr Ang. By swiftly integrating cross-functional teams and leveraging synergies, businesses can grow substantially in productivity and order fulfillment.

Coupled with an integrated MRP tool, timely delivery of orders becomes the norm, propelling operational efficiency to new heights.

Example of S&OP timeline

Leave a Reply