3 mistakes to avoid when it comes to achieving supply chain excellence

Through 2024, 50% of supply chain organizations will invest in applications that support artificial intelligence and advanced analytics capabilities. The COVID-19 pandemic amplified the need for supply chain organizations to seek tools that help them make smarter decisions faster.

In the last supply chain blog post, we touched on business process management (BPM) and how BPM ensures competitive advantage with your supply chain to achieve business success.

As a recap- the supply chain will be a key element to shape the future of businesses- and is the weapon for competitive advantage (McKinsey 2021). If that’s the case, we mustn’t turn a blind eye to what might potentially weaken the supply chain system.

In our last and final blog post of the supply chain series, we will be touching on the 3 mistakes to avoid when it comes to achieving supply chain excellence and how to integrate Business Central seamlessly into your inventory management.

Let’s discuss further below.

Mistake 1: Lack of visibility and agility

The old saying from Peter Drucker goes, “You can’t manage what you can’t measure.”

How can we become more resilient to changes across the supply chain, or meet sustainability goals, if we do not have the information to make informed decisions?

Below are 3 easy to digest ways to counter the mistake:

-

Understanding product life cycles

-

Product life cycles will get shorter, and businesses must master the shorter product life cycles and volatile business environments (McKinsey 2020).

-

How? Supply chains can become agile by focusing attention across production, capital assets, purchasing, product development and planning within the product life cycles.

-

-

Agility through automation

-

Automation. ERP. Technology. Does it all sound familiar? The necessary levels of control and agility can only be achieved by creating reliable, repeatable processes that improve efficiency and reduce the risk of costly mistakes.

-

How? Adopting automation in coding and marking can provide manufacturers with a full, seamless communication channel, as well as options for increased visibility and data sharing.

-

-

Mitigating the risks

-

-

To mitigate risks with security of supply, many mining organizations have assessed or implemented an action plan that creates an alternative supplier for key categories.

-

How? Some companies have moved toward a more sustainable and local supply base.

-

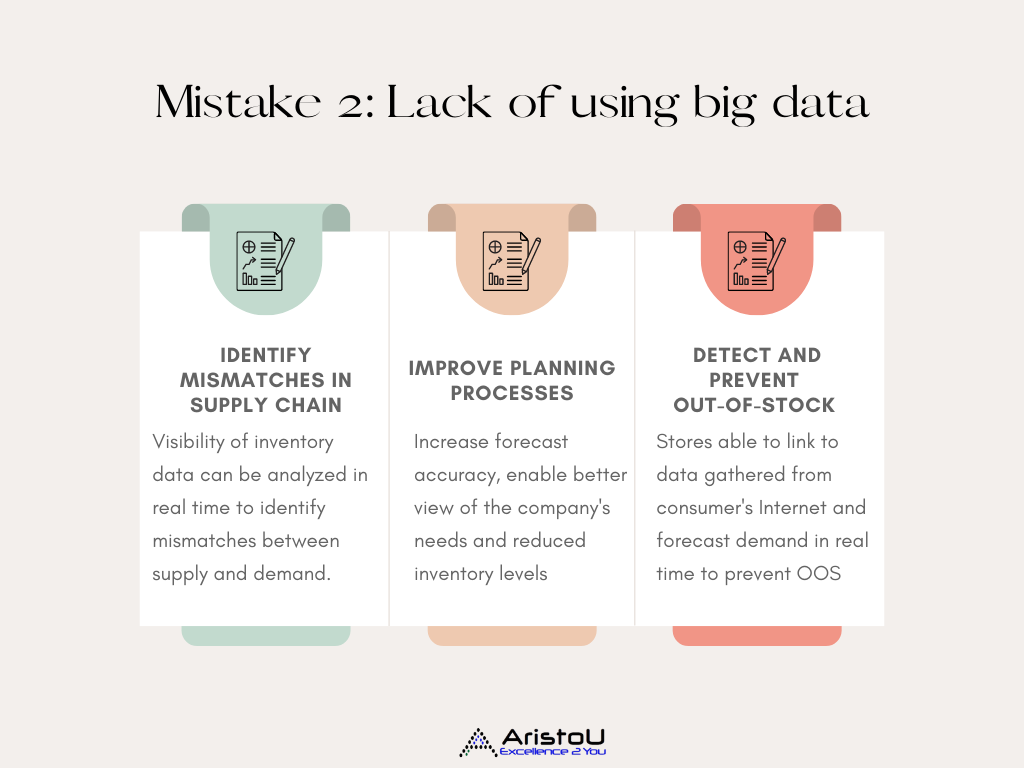

Mistake 2: Lack of using big data

“The most valuable commodity I know of is information”- Gordon Gekko. Big data is already here. The era of digital means a big analytics landscape for the supply chain to work with.

The best part? It applies data and quantitative methods to improve decision making for all activities across the supply chain.

Below are 3 easy to digest ways big data helps the supply chain:

-

Identify inconsistencies between supply and demand in real time

-

Visibility of point of sale (POS) data, inventory data, and production volumes can be analyzed in real time to identify mismatches between supply and demand.

-

These can then drive actions, i.e: price changes, the timing of promotions, addition of new lines etc to realign things.

-

-

Improve planning processes

-

Increase forecast accuracy; enabled a better view of the company’s logistics capacity needs; and reduced obsolescence, inventory levels, and stockouts.

-

With stronger demand-sensing capabilities, shaping demand towards consumers using big data analytics and recommending products to customers accordingly.

-

-

Detect and prevent out-of-stock

-

Manual inspection of stocks is laborious and expensive, and many retailers are now monitoring sales activity for out of stock indicators.

-

Whilst innovative technologies are also being tested to monitor on-shelf stock levels- with the advancement of big data, stores may be able to link to data gathered from consumer’s Internet-connected refrigerators to forecast demand in real time.

-

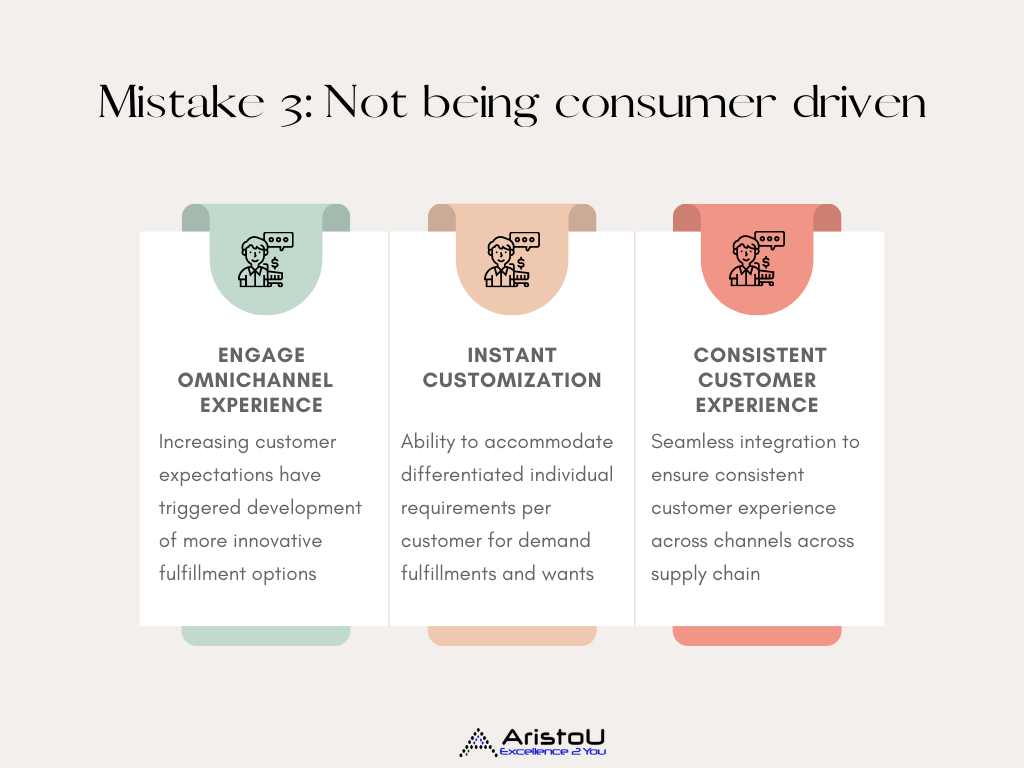

Mistake 3: Not being consumer driven

A rule of thumb to live by: If you’re not for the customer, you’re against the customer. Allow your supply chain to be consumer centric and driven.

Supply chains will devise micro segments and provide tailored offerings to satisfy the growing and demanding consumers. The advent of social networking has provided the potential to understand customer mindsets, and organizations will increasingly tap leads through social media for targeted promotions.

As consumers become more demanding, supply chains will become more complex and responsive.

Below are 3 easy to digest ways how supply chain can be consumer driven:

-

Engaging omnichannel shopping experience

-

Consumers prioritize not just products but an engaging omnichannel shopping experience. They want: convenience, personalization, economy, and social responsibility.

-

Rising customer expectations for faster delivery have triggered the development of more innovative fulfillment options

-

-

Instant customization

-

Enabled by new technology to fulfill rising customer expectations, such as for instant customization

-

Ability to meet differentiated requirements for demand fulfillment in different categories and geographic markets, while taking into consideration other factors that increase volatility

-

-

Ensure consistent customer experience

-

Supply chain integrated seamlessly across all channels to ensure consistent customer experience (through advanced planning, distributed-order management, and excellence in physical flows)

-

The supply chain has to be geared to capture interested consumers and provide products/services on time every time.

-

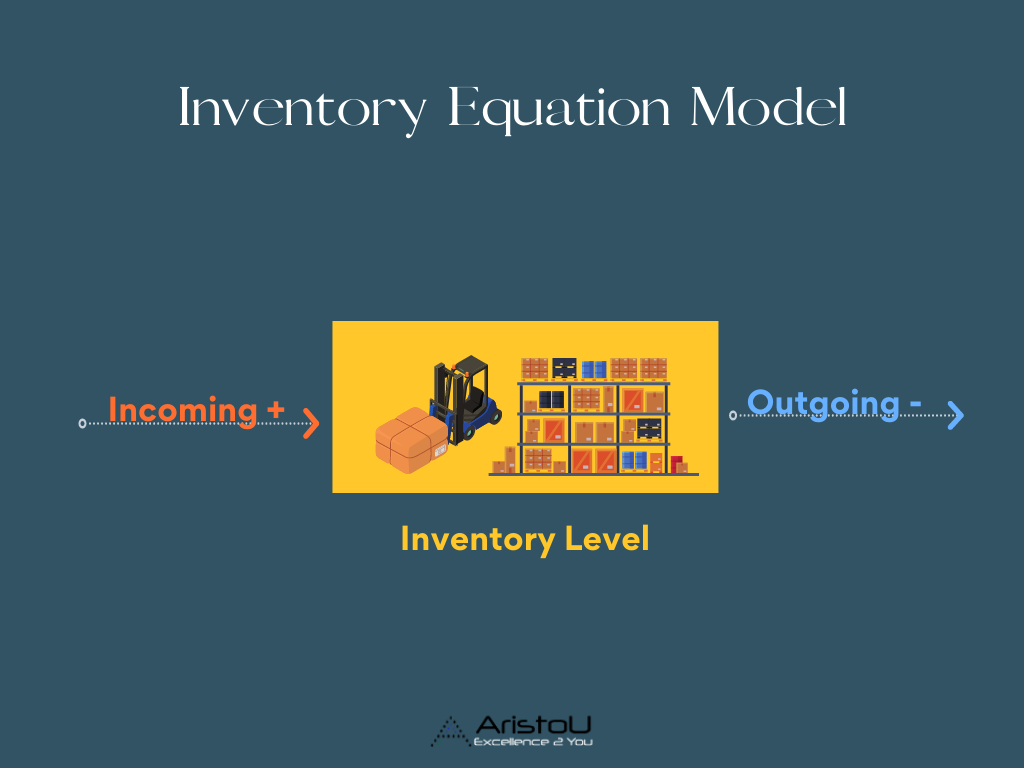

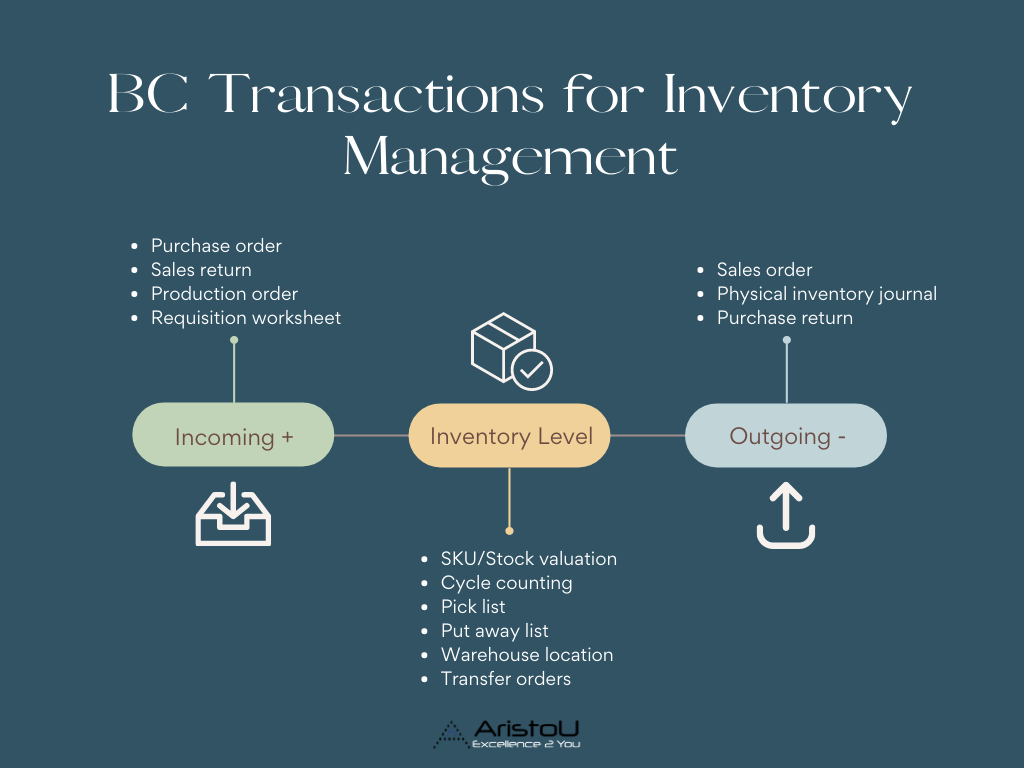

Now that we’ve gotten the 3 mistakes out of the way, let’s have a look at a simplified inventory equation model below and how ERP plays a role in it.

Inventory Equation Model

As a rule of thumb, Inbound logistics brings supplies or materials into a business, while outbound logistics deals with moving goods and products out to customers.

Both surround the flow of transportation of goods- inbound is all about receiving, while outbound is all about delivering.

The above inventory equation model implies how to manage inventory at a fundamental level. It helps businesses in 5 ways:

-

Determining the optimal level of inventories

-

Managing frequency of ordering

-

Deciding on quantity of goods/raw materials to be stored

-

Tracking flow of supply of raw materials and goods

-

Provide uninterrupted service to customers without any delay in delivery

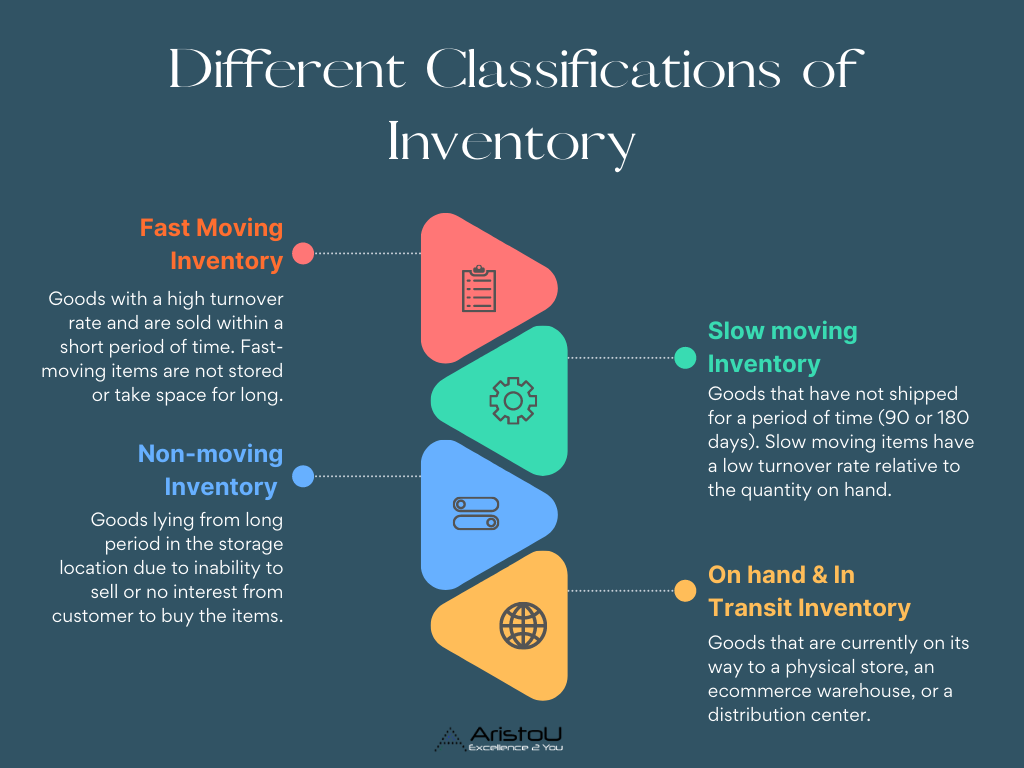

Different classifications of inventory

Each class of inventory would require a different set of actions to manage. In this segment, we’ll zoom in on 4 different classifications of inventory.

1. Fast Moving Inventory

-

Fast moving inventory are goods with a high turnover rate and are sold quickly in a short amount of time.

-

Fast moving items are not stored or take space for long, which is favorable for businesses.

2. Slow Moving Inventory

-

Slow moving inventory are goods that haven’t been shipped for a period of days and have low turnover rate relative to the quantity on hand.

-

The challenge with having slow-moving inventory is that it physically eats up space and ties up capital, which can impede cash flow and thus impact your business.

3. Non Moving Inventory

-

Non moving inventory are goods lying dormant from a long period in the storage location due to an inability to sell.

-

When inventory doesn’t move, there are associated carrying costs and it ties up valuable capital and resources that could otherwise be used to invest in your business.

4. On hand & In Transit Inventory

-

In transit inventory are goods on its way to a physical store, supplier, ecommerce warehouse or a distribution center

-

On hand inventory is the amount of stock items available to a retail outlet ready to be immediately sold or used by consumers.

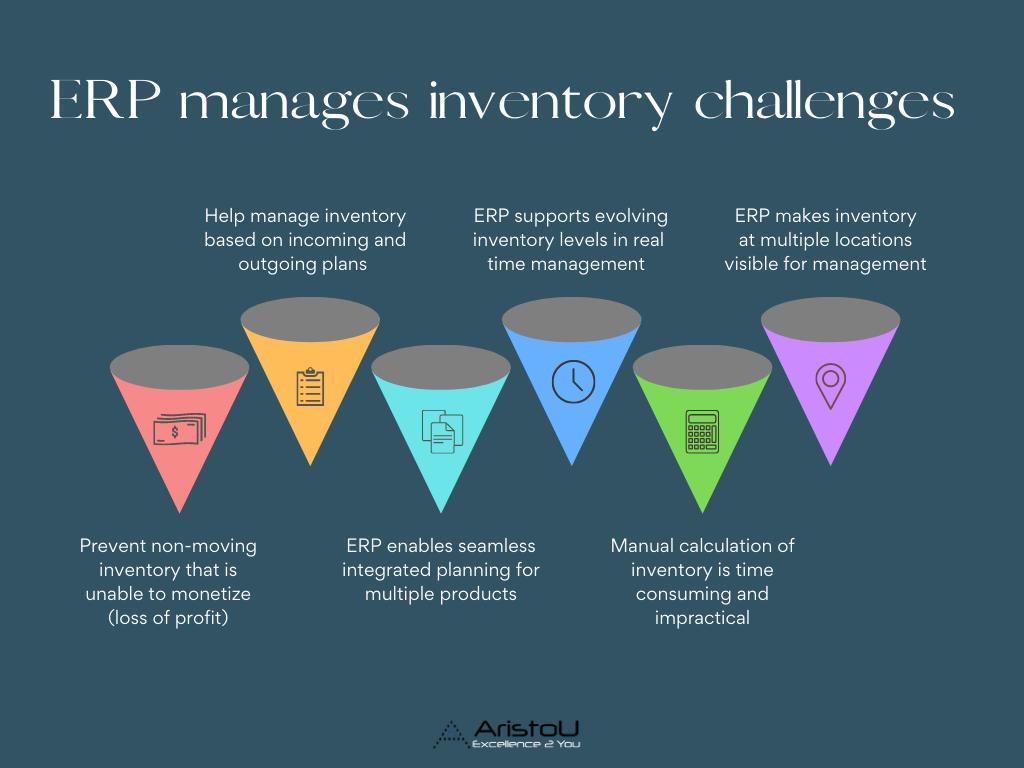

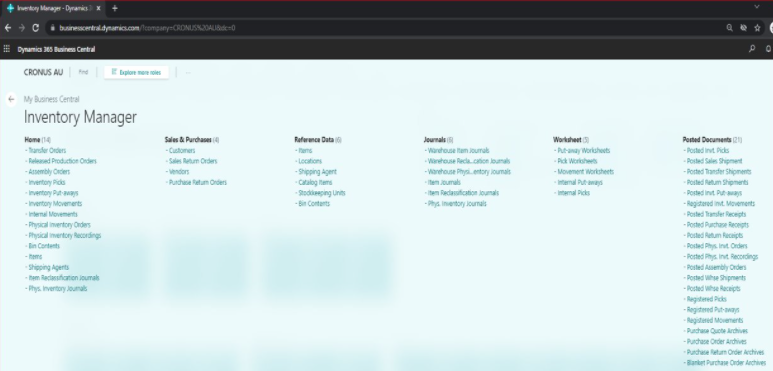

How Business Central alleviates Inventory challenges

ERP driven inventory management increases efficiencies throughout the supply chain. In 2022, it is almost impossible for any scaling and growing organization not to have an ERP system if they want to remain competitive.

How then, does Dynamics 365 Business Central respond to the needs of distribution companies?

In Microsoft Business Central, you’re able to draw on a variety of data sources to help companies better understand the performance history of various SKUs, among many other insights- the possibilities are endless.

In the case of a warehouse, a well-configured system can significantly shorten the time of product complementation and minimize the costs associated with the relocation of inventory.

Warehouse and inventory management in Dynamics 365 Business Central

Business Central has vast capabilities that can help support your warehouse and inventory management system. Let’s take a look at some of the inventory management functions sitting within Business Central.

Business Central allows complete automony over product management path

-

Begin with defining the method of receiving and allocating inventory, from warehouse, posting and assigning goods to the appropriate stock level.

-

Managing the goods is integrated with the financial department, making each move visible in the financial module

-

E.g. in the form of an invoice or a delivery note.

-

Various types of sales and purchasing documents are supported

-

Includes bulk sales and purchase orders

-

The user has the option of issuing invoices without the need to register the order

-

For specific buyers, you can define separate prices depending on the given criteria

-

E.g. the minimum value or quantity of the order (moreover, the discount can be defined in the sales document).

-

Automates necessary functions

-

Business Central has functionality optimized for inventory management ensuring that stock purchasing, organizing and transferring are in sync.

-

Helps maintain optimal levels of stock by integrating the inventory needs of staff, customers and suppliers.

-

As a centralized system, it can cut down on double-handling of goods and automate daily tasks, like reordering.

With business central, you are able to utilize this data to make more informed ordering decisions and create more accurate forecasts to meet future demand, without ending up with excess stock.

Leave a Reply