Enhancing Warehouse Efficiency with Barcode Implementation

The development of technologies in the digitalized era has developed rapidly. Entering the industrial revolution 4.0, all of our life aspects need a touch of technology (Istiqomah et al., 2020).

And technology isn’t an exception.

Technology has sped up and simplified every task. One of those technologies that we currently use in the industrial revolution 4.0 within the logistics industry is Barcode implementation.

As we know, supply chain management helps businesses gain competitive advantage in the market and warehouse logistics plays a vital role in the supply chain when it comes to managing and maintaining the inventory accurately and efficiently.

According to research conducted by (Istiqomah et al., 2020), barcode implementation in the warehouse management system to achieve warehouse efficiency.

Let’s delve into the implementation of barcodes, specifically emphasizing on the examination of the Tasklet WMS Scanner.

What is a Warehouse Management System (WMS)?

Warehouse Management Systems (WMS) is a database information technology that manages all warehouse processes in the IT systems by coordinating integrated storage activity and maintaining accurate inventory and warehouse operational efficiency.

WMS plays a key role in communicating with customers and external partners in sharing information electronically for shorter lead time and channel visibility in processing the customer request (Andiyappillai, 2019).

The purpose of the WMS is to better manage every process that occurs within the warehouse such as receiving, putaway, order processing/picking, outbound checking, loading, stock take which we will cover in the next segment below.

With the right technology in place, the computerized WMS is utilized as a tool to control goods availability in the warehouse.

What kind of current systems/traditional methods are used in WMS?

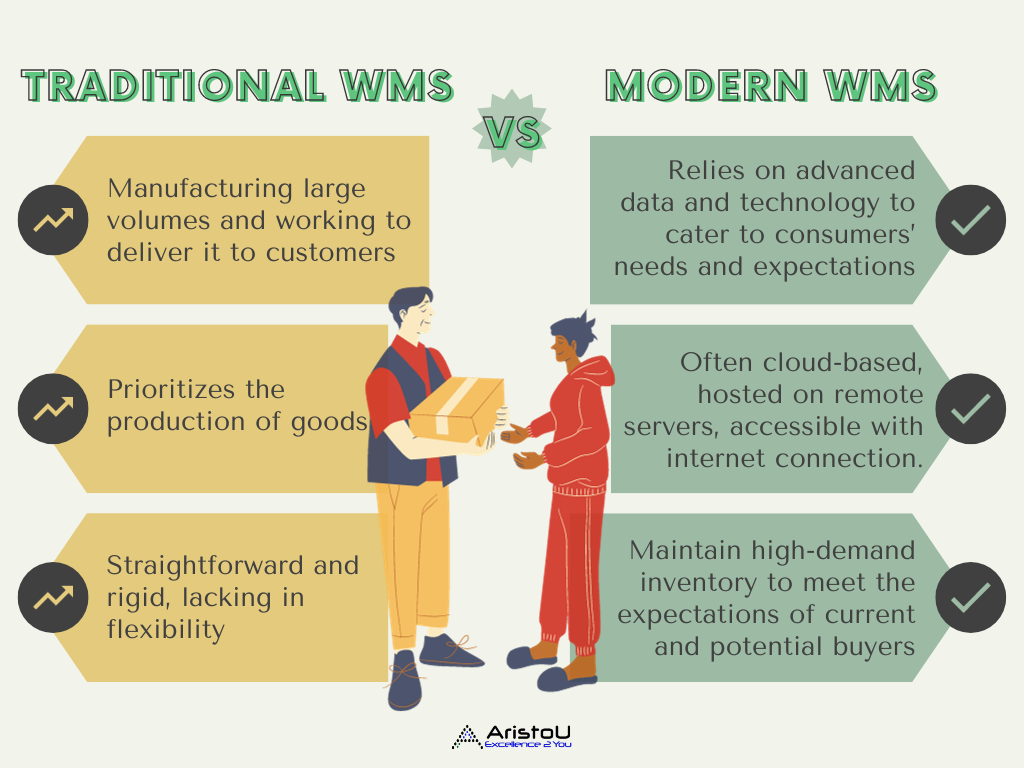

1. Traditional WMS

-

The traditional supply chain management prioritizes the production of goods. It focuses on finding a worthwhile product, manufacturing large volumes, and working to deliver it to customers.

-

The pathway is straightforward and rigid, not allowing for a lot of flexibility.

2. Modern WMS

-

On the other hand, modern supply chain management relies on advanced data and technology to cater to consumers’ needs and expectations. Modern WMS systems are often cloud-based, hosted on remote servers, making them accessible from anywhere with an internet connection.

-

It employs logistics to ensure operations run smoothly and efficiently and utilizes technology advancements and intelligent data collection to focus on customizing products to meet customers’ needs.

-

Results? Maintaining high-demand inventory to meet the expectations of current and potential buyers.

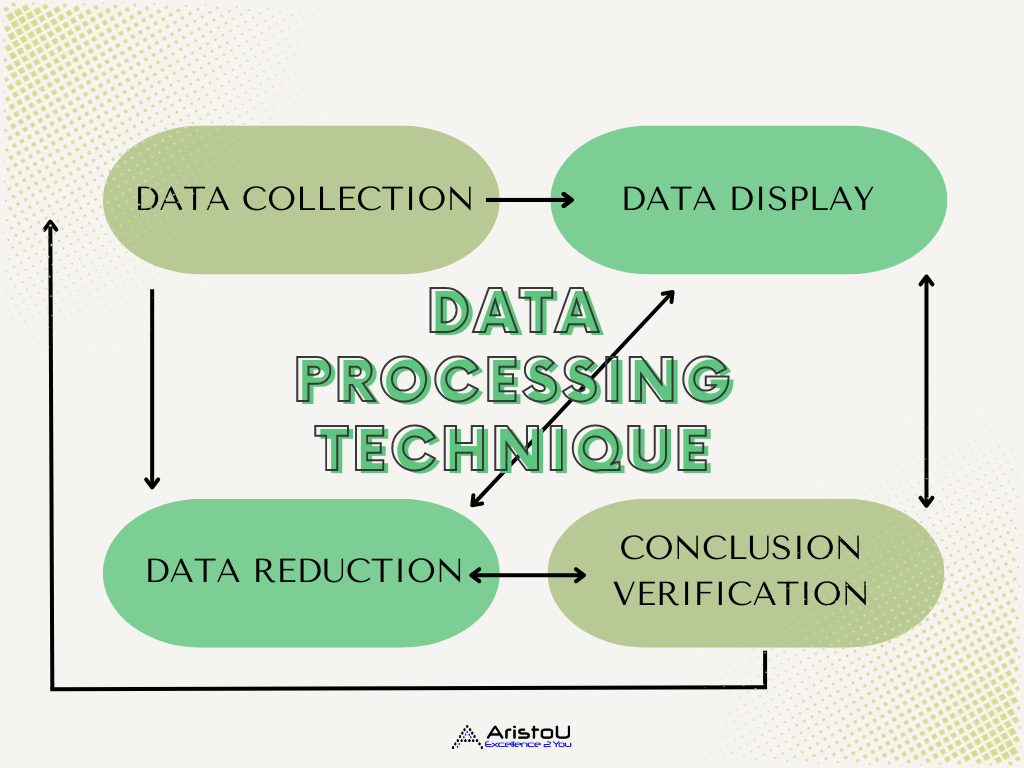

Data in Warehouse Management System

Warehouse Management Systems help to capture the warehouse operational and process data in the system.

This is an important task for any warehouse management team to capture the necessary data and use them to mitigate the challenges that they face; faster product cycle, dynamic market behavior, extreme customer expectations and cost benefits.

The data that are stored in WMS can be from multiple sources and can be made available as long as the business needs it.

Research (Andiyappillai, 2019) has shown the importance of the data analytics tools to analyze the WMS data for the visibility of each facility.

Solving warehouse management pain-points

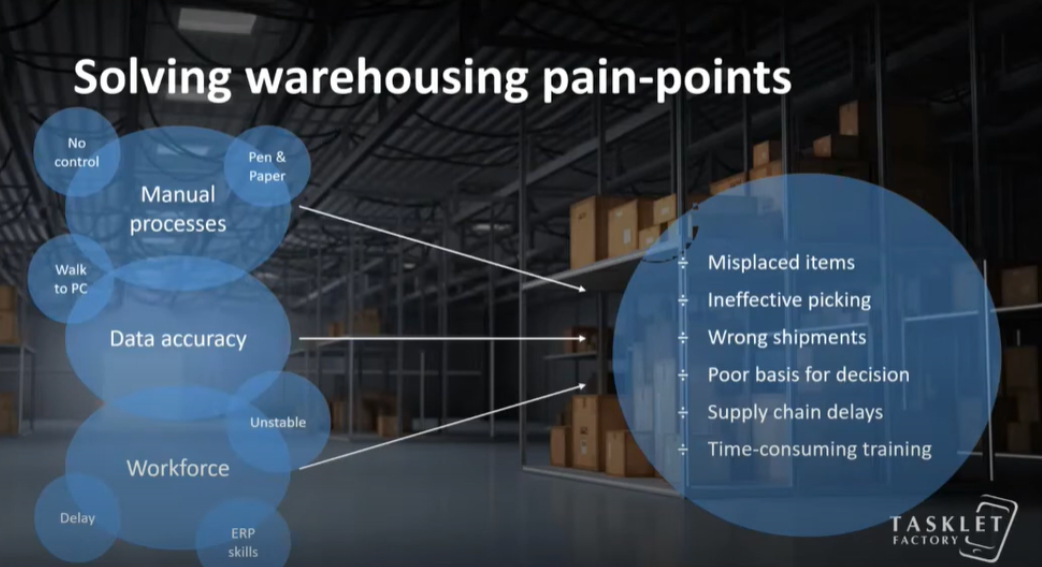

Problems occur in the supply and distribution of goods when the flow of goods is not smooth.

E.g: the layout of goods or items in the storage room will affect the business organization in terms of goods flow, quality, capacity, flexibility so that it will increase efficiency in the warehouse process.

According to Tasklet (2021), several key warehouse factors such as: manual processes, lack of data accuracy, and an inefficient workforce will result in pain points such as misplaced items, ineffective picking, wrong shipments, poor basis for decisions, supply chain delays, time consuming training etc.

Moreover, the modern user is expected to have a system that manages and records every goods that enters and exits the warehouse.

Why is warehouse management important?

The warehouse contains fundamental functions that support goods movement, product storage, cargo groupings, stock collection storage and assembling the shipments.

When you have the right tools like Tasklet to manage your warehouse well, you gain a competitive advantage to the organization.

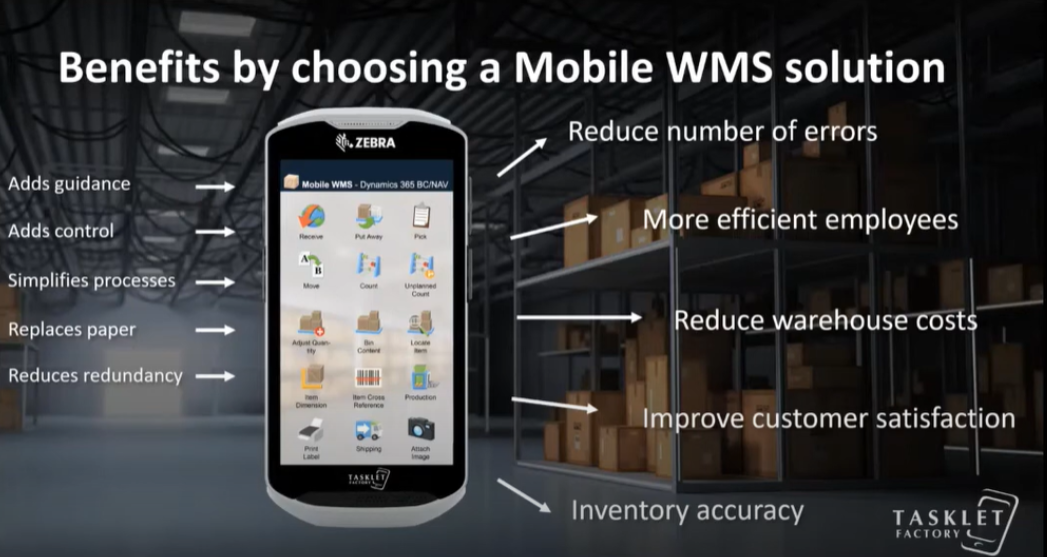

Let’s look at some of the benefits you will get from a strong WMS with the use of barcodes:

The implementation of barcode in warehouse management system has many benefits:

1. Speeding up goods in and out of the warehouse in real time

2. Identify goods and the location to simplify racking and picking

3. Improve data accuracy

4. Improves customer service

5. Reduce possibility of stock out

6. Reduce handling costs in warehouse

7. Reduce human errors that occurs due to manual handling

Understanding Tasklet Barcode Scanner Technology

The physical inventory with the barcode scanning speeds up the inventory process (Gašpar et al., 2012). When the barcode is scanned, the application automatically finds the corresponding item and shows its properties.

Here’s a step by step walkthrough of how the barcode implementation technology using Tasklet works:

1. Scanning Barcodes:

-

-

Users equipped with mobile devices or scanners scan barcodes affixed to products, storage locations, or paperwork in the warehouse. These barcodes could be in the form of traditional 1D barcodes or more advanced 2D barcodes (like QR codes).

-

2. Data Capture:

-

-

The scanner captures the information encoded in the barcode, which could represent a product’s SKU, a location code, or other relevant data. The captured data is typically in a machine-readable format.

-

3. Data Transmission:

-

-

The scanned data is transmitted wirelessly to the warehouse management system (WMS) or an ERP system (like Microsoft Business Central) in real-time. This communication can occur over Wi-Fi, cellular networks, or other wireless technologies.

-

4. Data Processing:

-

-

The WMS processes the received data. It may involve tasks such as updating inventory records, confirming order fulfillment, verifying product locations, or generating picking instructions.

-

5. Task Allocation:

-

-

Based on the processed data, the WMS assigns specific tasks to warehouse workers. E.g: it may instruct a picker to gather items for a specific order and provide the location information.

-

6. Task Execution:

-

-

Warehouse personnel follow the instructions provided on their mobile devices, guided by the scanned barcode data. They retrieve items from storage locations or perform other warehouse operations as directed.

-

7. Real-time Updates:

-

-

As tasks are completed, the WMS receives real-time updates from the mobile devices. This information is used to maintain accurate inventory records, monitor order progress, and track the movement of items within the warehouse.

-

The user can choose whether he wants to add or remove the scanned item from the inventory count. After the inventory is finished, the user sends all records to the ERP system with one click on the diskette icon.

-

Tasklet barcode scanner technology streamlines warehouse operations by providing real-time visibility and control over inventory and tasks.

It minimizes human errors, enhances operational efficiency, and contributes to a more organized and productive warehouse environment.

-

Tasklet WMS Implementation

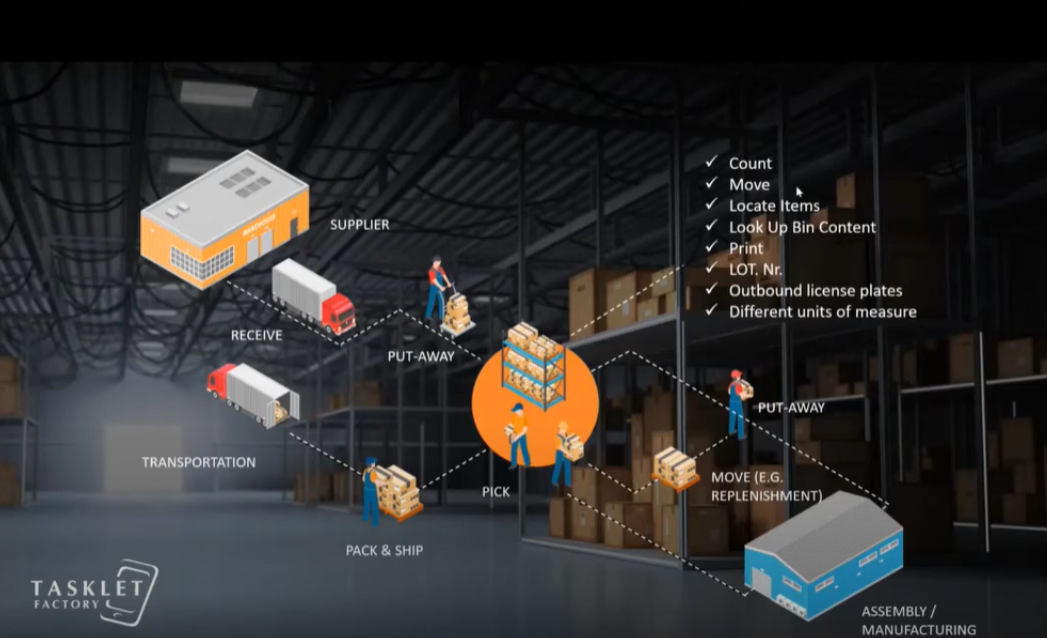

The implementation of the barcode in every process in Tasklet’s Warehouse Management System is as follows:

-

Receive- Register and control items against purchase orders. Supports expiry dates, LOT and serial numbers

-

Put Away- Assign a shelf (BIN) to the received items

-

Pick- Pick items and prepare them for shipment or production as single or consolidated orders

-

Count- Count items according to inventory journals or as unplanned counts

-

Move- Perform planned or unplanned movements of item

-

Bin Content- Look-up the content of a warehouse shelf (BIN)

-

Locate Item- Look-up the location and the quantities of an item

-

Adjust Quantity- Remove items from the inventory and provide a reason code

-

Item Cross Reference- Associate a barcode with an item

-

Substitute Item- Look-up substitute item

-

Print- Initiate print of reports/labels from the mobile device

-

Shipping- Enter shipping and carrier information to speed up processing

The implementation of barcodes on the warehouse management system is able to increase efficiency in warehouses.

Every process in the warehouse that has been equipped with barcodes can be done faster and more directed than the warehouse that still uses manual handling (Istiqomah et al., 2020).

In the research conducted by (Andiyappillai, 2019), it was demonstrated that the organization gained competitive advantage by delivering the right product in the right place at the right time through the deployment of data analytics and reporting tool.

Importantly, this company has observed that this data analytics tool provides the ROI very clearly to the business as it helps the better informed decision makings, business growth, capacity and capability.

Want to achieve the same results as this company? It might be time to ditch your outdated traditional supply chain management system for a modern, data driven barcode implementation WMS like Tasklet Factory.

Aristou’s expertise in Tasklet Barcode scanner for your warehouse management might just be what you need. Talk to an Aristou expert today to learn more!

Find out more

-

View all Aristou Pte Ltd content on resources-blog

-

View our first ISV solution Active Budget Check

-

Read more about our first ever internal Power Platform Seminar here

Leave a Reply